How Batik Is Made

Batik fabric: what is it, where does it come from and how do they really do that? This summary will address basic questions about these gorgeous fabrics.

First a definition straight from Merriam Webster

"batik (n): a fabric printed by a method of hand-printing textiles by coating with wax the parts not to be dyed". Although there are many types of "resist" that can be used, wax is the most common. Beeswax, paraffin wax, and resins can be purchased already mixed, or custom mixed by the artist.

The Creative Genius of Batik Artisans

Unlike commercial screen printed fabrics, Batiks are still made by hand using the traditional wax and dye methods. These methods are as unique as the country in which they are produced.

There are numerous methods of applying the resist to the fabric. The three most common are:

1. using a tjanting (pronounced chanting) tool for free hand drawing each and every line and dot in the design;

2. applying the wax to the fabric by hand using a metal or wooden tool; and

3. using a thick hard foam sponge or brush to apply the resist.

For production fabrics (a very loose term when applied to handmade fabrics), thick hard foam sponges are the method of choice in Tanzania, simply because they are faster to use.

The hot wax surrounds the fibers in the fabric and resists the movement of dye into them. In other words, when the waxed fabric is submerged in a dye bath, the fabric under the wax resists the dye, and stays the same color as it was before dyeing.

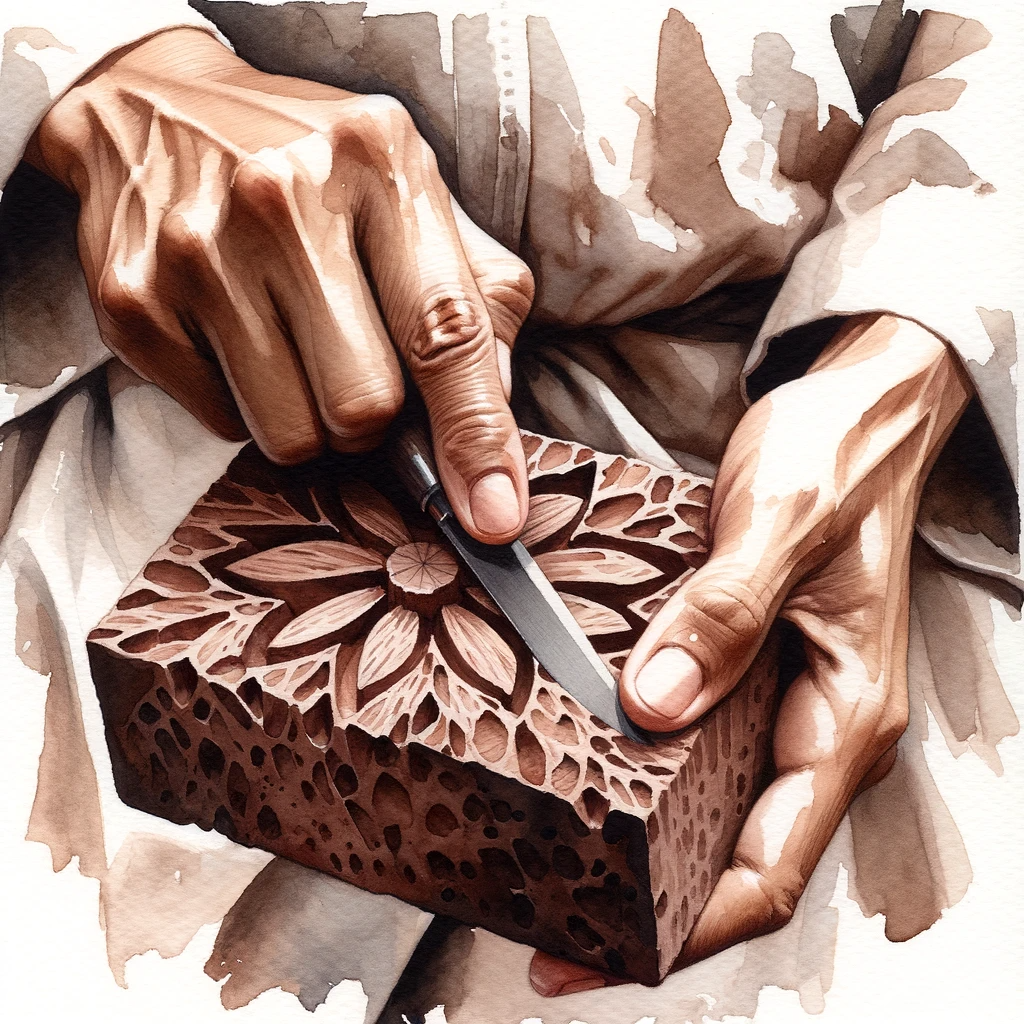

Once a design has been approved for production, an artist makes a hand tool, for stamping, by carving out the design on one end of the hard foam block of sponge. Depending on the number of colors and patterns in the design, a series of hard form blocks of sponge are made for the desired design. The blocks of sponge are used to carry the hot wax to the fabric.

Sounds fairly simple, right? Well, many people prefer the multi-color designs as opposed to the simple two-color design from one round of wax and dye, so the artists need to understand what will happen with the designs and colors when they repeat the process for subsequent dye baths.

The preferred fabric used to produce Batik is 100% cotton, a ready to dye fabric. To simplify the process of creating a complex Batik design with many colors, the artists may use one or many techniques prior to the first application of wax. These dyeing techniques range from simple dyeing with a single color to hand painting the goods, to treating the fabric with sea salt or gathering and tying the fabric to produce unique background patterns.

After the initial dyeing, the fabric is carried by hand outside to dry in the tropical sun. Once dry, it is hand carried back inside to receive an application of wax and the process continues.

If the sponge design blocks are imprinted carefully, it is virtually impossible to see that each length of fabric has 9 to 12 different sets of the imprint. More complex designs can easily have twice that number of imprints put on at two or three different times with dyeing, hand painting, and drying in between.

Considering the volume of fabric produced, many people think that it is produced with the help of machines. Batik fabrics are not--the most complex machines used in the process are strong gloved hands to wring the fabrics!

The majority of Batik fabrics available for purchase today are imported to the United States from Indonesia. One of the primary objectives/goals of VAPOA Company Limited (Value-Added Products Out of Africa) is to export this beautifully produced fabric directly from Tanzania to the US. We are partnering with Batik artisans, primarily women, who make Batik fabrics and women fabric crafters (tailors) who use the Batik fabrics to construct premium high-quality products now being exported from Tanzania and sold in the US and global markets.

Unlike commercial screen printed fabrics, Batiks are still made by hand using the traditional wax and dye methods. These methods are as unique as the country in which they are produced.

We hope this brief description of the Batik process will give you a new and informed appreciation for what goes in to making this beautiful handmade fabric.

The next time you are using your TanzaTōtz Collection accessory made from beautiful Batik fabrics by Tanzanian women artisans and crafters, imagine the warm sun drying the fabric south of the equator in East Africa.